Delving into the intricacies of what is true about a carburetor backfire flame arrestor unveils a fascinating realm of knowledge. This comprehensive guide delves into the depths of this essential component, exploring its purpose, design, types, installation, maintenance, and safety considerations, providing a comprehensive understanding for those seeking enlightenment.

The flame arrestor, a guardian against combustion’s wrath, plays a crucial role in ensuring the safe operation of carburetor-equipped engines. Its intricate design and meticulous construction prevent the spread of flames, safeguarding against catastrophic consequences.

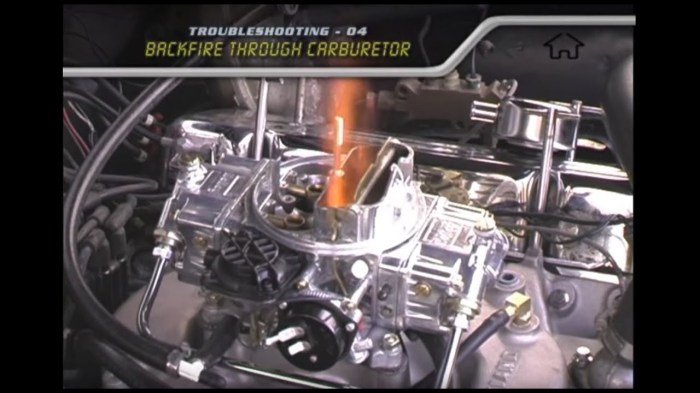

Carburetor Backfire Flame Arrestor Overview

A carburetor backfire flame arrestor is a safety device installed in the air intake system of an internal combustion engine, particularly in carburetor-equipped engines. Its primary purpose is to prevent the spread of flames or explosions from the carburetor back into the air intake, potentially causing severe damage or injury.

Flame arrestors are typically constructed from durable materials such as aluminum, stainless steel, or brass to withstand the harsh operating conditions and high temperatures within the engine compartment.

Flame Arrestor Design and Function: What Is True About A Carburetor Backfire Flame Arrestor

A carburetor backfire flame arrestor consists of a housing or body that encloses a mesh or screen element. The mesh is designed to quench flames by dissipating heat and interrupting the flame front propagation. The specific design and construction of the flame arrestor vary depending on the engine application and safety requirements.

When a backfire occurs in the carburetor, the flame is directed into the flame arrestor housing. The mesh or screen element acts as a barrier, breaking up the flame into smaller pockets and dissipating its energy. The quenching effect of the mesh prevents the flame from propagating back into the air intake and reaching the fuel source, minimizing the risk of an engine fire or explosion.

Types of Carburetor Backfire Flame Arrestors

There are various types of carburetor backfire flame arrestors available, each with its own advantages and disadvantages:

- Screen-type flame arrestors:Utilize a single or multiple layers of fine mesh or screen material to quench flames. They are relatively simple in design and cost-effective.

- Cellular-type flame arrestors:Employ a honeycomb-like cellular structure to dissipate heat and extinguish flames. They offer higher flame arrestment efficiency compared to screen-type arrestors.

- Hybrid flame arrestors:Combine elements of both screen-type and cellular-type arrestors to achieve a balance between cost and performance.

| Type | Advantages | Disadvantages |

|---|---|---|

| Screen-type | Low cost, simple design | Lower flame arrestment efficiency |

| Cellular-type | High flame arrestment efficiency | Higher cost, more complex design |

| Hybrid | Balance of cost and performance | May not offer the highest level of flame arrestment |

Installation and Maintenance of Flame Arrestors

Proper installation of a carburetor backfire flame arrestor is crucial for ensuring its effectiveness and safety:

- Locate the correct mounting point on the carburetor or air intake system.

- Clean the mounting surface and apply a gasket or sealant if necessary.

- Securely tighten the flame arrestor using the specified bolts or screws.

- Inspect the flame arrestor regularly for any signs of damage or clogging.

Cleaning and servicing the flame arrestor involves removing it from the engine, disassembling it, and cleaning the mesh or screen element using a solvent or compressed air. Reassemble the flame arrestor and reinstall it on the engine.

Safety Considerations

Carburetor backfire flame arrestors play a vital role in preventing engine fires and explosions. Malfunctioning or improperly installed flame arrestors can pose significant safety hazards:

- Fire risk:A damaged or clogged flame arrestor can allow flames to reach the fuel source, leading to an engine fire.

- Explosion hazard:If a flame propagates back into the air intake and reaches the fuel tank, it can cause an explosion.

To ensure the safe operation of flame arrestors, it is essential to adhere to safety regulations and standards, regularly inspect and maintain the arrestors, and promptly replace any damaged or malfunctioning components.

Essential FAQs

What is the primary function of a carburetor backfire flame arrestor?

To prevent the propagation of flames from the carburetor into the intake manifold and air cleaner, minimizing the risk of engine fires and explosions.

What materials are commonly used in constructing flame arrestors?

Stainless steel, aluminum, and bronze are commonly employed due to their durability, corrosion resistance, and ability to withstand high temperatures.

How does a flame arrestor prevent the spread of flames?

The mesh or screen material within the arrestor acts as a flame quenching barrier, dissipating heat and interrupting the flame’s path, effectively preventing its propagation.