A cast in place monolithic concrete building is – A cast-in-place monolithic concrete building is a testament to the enduring strength and versatility of this construction method. This technique involves pouring concrete directly into forms on-site, creating a seamless and robust structure that offers numerous advantages. Delving into the intricacies of cast-in-place monolithic concrete buildings, this comprehensive guide explores their design principles, construction techniques, and diverse applications, showcasing their exceptional capabilities in modern architecture.

From towering skyscrapers to sprawling industrial complexes, cast-in-place monolithic concrete has left an indelible mark on the built environment. Its inherent strength, durability, and fire resistance make it an ideal choice for structures that demand exceptional performance and longevity.

Cast-in-Place Construction

Cast-in-place concrete construction involves pouring concrete directly into formwork at the construction site. This method allows for the creation of monolithic structures, where the concrete is poured in one continuous operation without joints or seams.

Advantages of cast-in-place construction include:

- Design flexibility: Cast-in-place concrete can be molded into any shape or size, allowing for complex architectural designs.

- Durability: Concrete is a strong and durable material that can withstand various environmental conditions.

- Fire resistance: Concrete has excellent fire resistance, making it suitable for buildings that require high levels of safety.

Disadvantages of cast-in-place construction include:

- Time-consuming: The construction process can be time-consuming, especially for large-scale projects.

- Labor-intensive: Cast-in-place construction requires a skilled workforce and specialized equipment.

- Weather dependency: The construction process can be affected by weather conditions, such as rain or cold temperatures.

Examples of structures commonly built using cast-in-place concrete include bridges, tunnels, skyscrapers, and dams.

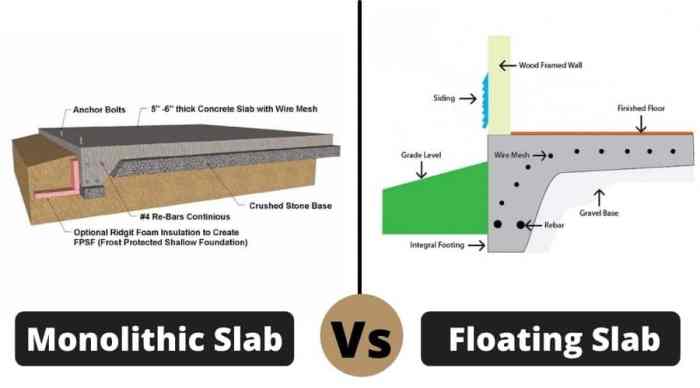

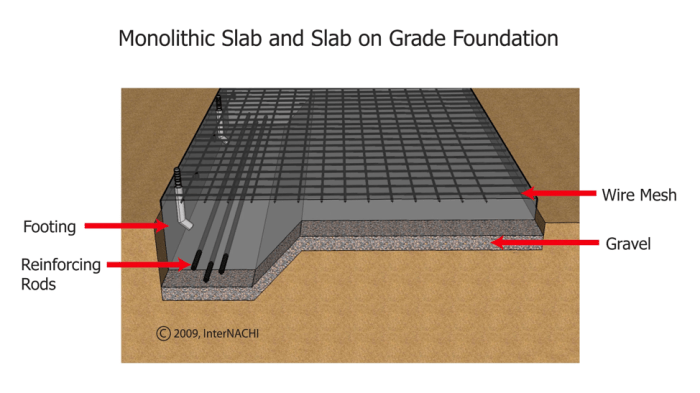

Monolithic Construction

Monolithic construction refers to structures built from a single piece of concrete, without joints or seams. This method provides several benefits:

- Structural integrity: Monolithic structures are highly resistant to earthquakes and other seismic events due to their seamless design.

- Waterproofing: The absence of joints or seams eliminates potential water infiltration points, making monolithic structures highly waterproof.

- Durability: Monolithic concrete structures are less susceptible to cracking and deterioration compared to structures with joints.

Challenges associated with monolithic construction include:

- Formwork design: Designing formwork for monolithic structures can be complex, especially for curved or irregular shapes.

- Concrete placement: Pouring concrete in one continuous operation requires careful planning and execution to ensure proper consolidation and avoid defects.

- Temperature control: Controlling temperature during the curing process is crucial to prevent cracking and ensure optimal concrete strength.

Examples of monolithic concrete structures include the Burj Khalifa, the Sydney Opera House, and the Hoover Dam.

Materials and Properties

Cast-in-place monolithic concrete construction typically uses the following materials:

- Cement: Portland cement is the most common type of cement used in concrete.

- Aggregates: Coarse aggregates (such as gravel) and fine aggregates (such as sand) provide strength and volume to the concrete.

- Water: Water is essential for the hydration of cement and the formation of concrete.

- Admixtures: Admixtures can be added to modify the properties of concrete, such as strength, durability, or workability.

Cast-in-place monolithic concrete exhibits the following properties:

- Strength: Concrete is a strong and durable material with high compressive strength.

- Durability: Concrete can withstand various environmental conditions, including extreme temperatures, moisture, and chemicals.

- Fire resistance: Concrete has excellent fire resistance, making it suitable for buildings that require high levels of safety.

Factors that affect the properties of cast-in-place monolithic concrete include the mix design, curing conditions, and environmental exposure.

Design Considerations

The design of cast-in-place monolithic concrete buildings involves several key considerations:

- Structural analysis: Structural analysis is performed to determine the forces and stresses acting on the structure and to ensure its stability.

- Material selection: The selection of concrete materials and mix design is crucial for achieving the desired strength, durability, and fire resistance.

- Formwork design: Formwork design must be carefully planned to ensure the proper shape and dimensions of the concrete structure.

- Construction sequencing: The construction sequence must be planned to minimize the risk of cracking and ensure the proper curing of the concrete.

Innovative design approaches for cast-in-place monolithic concrete buildings include:

- Self-compacting concrete: Self-compacting concrete flows easily into formwork, reducing the need for vibration and improving consolidation.

- High-performance concrete: High-performance concrete exhibits superior strength, durability, and fire resistance compared to conventional concrete.

- Precast concrete elements: Precast concrete elements can be incorporated into monolithic structures to reduce construction time and improve quality.

Construction Techniques

The construction of cast-in-place monolithic concrete buildings involves the following techniques:

- Formwork erection: Formwork is erected to define the shape and dimensions of the concrete structure.

- Concrete placement: Concrete is poured into the formwork in one continuous operation.

- Consolidation: Concrete is consolidated using vibration or other methods to remove air pockets and ensure proper bonding.

- Curing: Concrete is cured under controlled temperature and moisture conditions to ensure optimal strength and durability.

Best practices for cast-in-place monolithic concrete construction include:

- Proper mix design: A carefully designed concrete mix is essential for achieving the desired properties.

- Adequate reinforcement: Reinforcement is used to provide tensile strength to the concrete structure.

- Quality control: Quality control measures must be implemented throughout the construction process to ensure the integrity of the structure.

- Skilled workforce: A skilled workforce is essential for the proper execution of cast-in-place concrete construction.

Applications

Cast-in-place monolithic concrete buildings are used in a wide range of applications, including:

- Residential buildings: Monolithic concrete structures provide durability, fire resistance, and sound insulation for residential buildings.

- Commercial buildings: Monolithic concrete structures are suitable for high-rise buildings, office complexes, and shopping malls.

- Infrastructure projects: Monolithic concrete structures are used in bridges, tunnels, dams, and other infrastructure projects.

Advantages of using cast-in-place monolithic concrete for different applications include:

- Design flexibility: Cast-in-place concrete can be molded into any shape or size, making it suitable for complex architectural designs.

- Durability: Monolithic concrete structures are highly durable and can withstand various environmental conditions.

- Fire resistance: Concrete has excellent fire resistance, making it suitable for buildings that require high levels of safety.

Disadvantages of using cast-in-place monolithic concrete for different applications include:

- Time-consuming: The construction process can be time-consuming, especially for large-scale projects.

- Labor-intensive: Cast-in-place construction requires a skilled workforce and specialized equipment.

- Weather dependency: The construction process can be affected by weather conditions, such as rain or cold temperatures.

Common Queries: A Cast In Place Monolithic Concrete Building Is

What are the advantages of cast-in-place monolithic concrete construction?

Cast-in-place monolithic concrete construction offers numerous advantages, including superior strength, durability, fire resistance, and design flexibility. It eliminates joints and weak points, resulting in a seamless and robust structure.

What are the challenges associated with monolithic concrete construction?

Monolithic concrete construction can be challenging due to its complex design and construction process. It requires careful planning, specialized equipment, and skilled labor to ensure proper execution and prevent cracking or other structural issues.

What are some examples of structures commonly built using cast-in-place monolithic concrete?

Cast-in-place monolithic concrete is widely used in various structures, including high-rise buildings, bridges, tunnels, dams, and industrial facilities. Its strength and durability make it suitable for demanding applications.